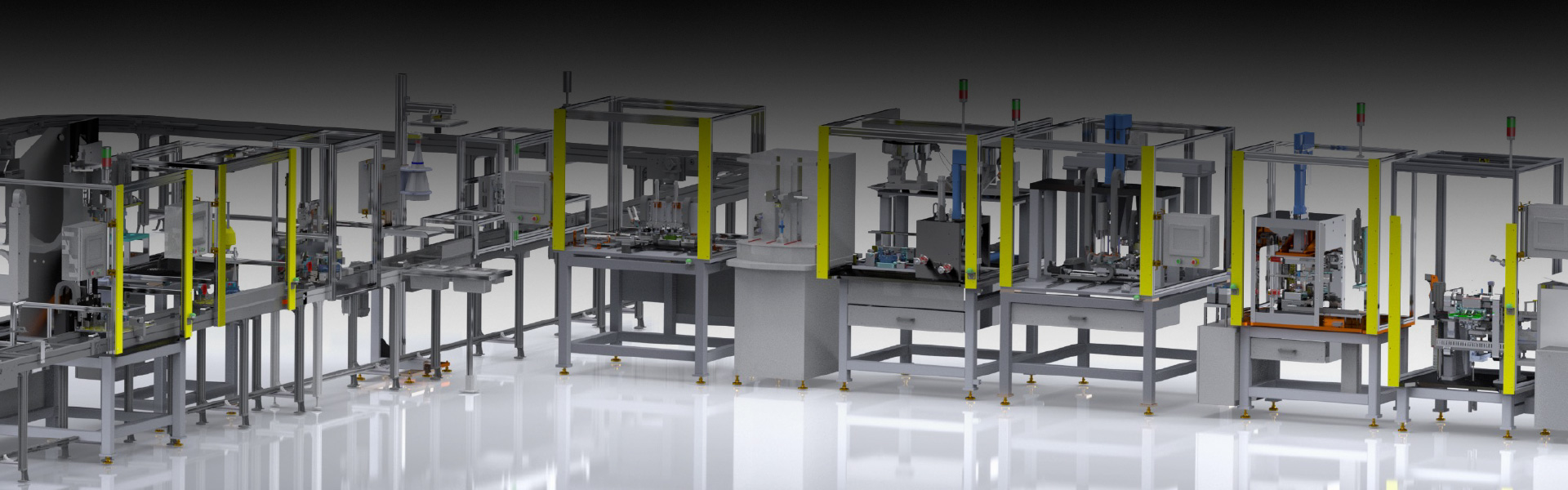

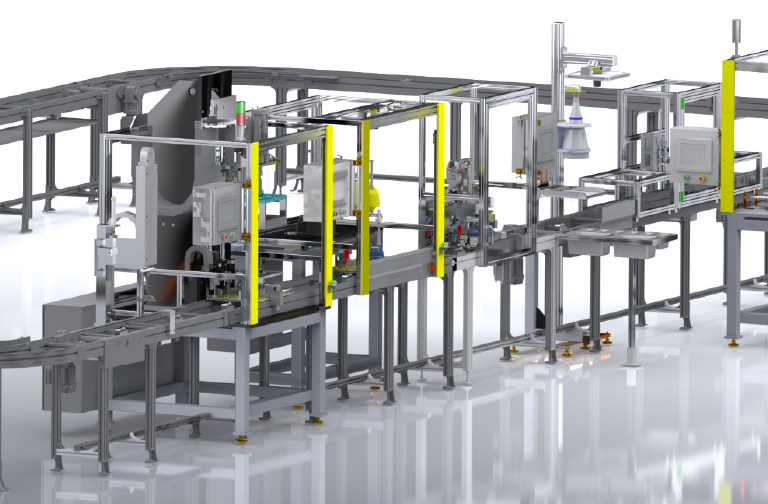

Automotive Oil Pump Assembly System

Customer Challenge

New product launch for Tier 1 automotive company

- Customer looking for a decrease in cycle time and to expand capacity

- Interfaces with clean room area and with existing cleaning equipment

- Multiple station, modular design with Poka-yoke

- Internal components to the assembly had to be error proofed

Profile:

Semi-Automated Power and Free assembly system with manual load stations.

Features

- High-precision shaft to rotor pressing operations

- Pallet-based, twin-belt conveyor, open center

- Allen Bradley Controls

- SCARA style Fanuc robots

- Semi clean room environment

- Multiple automated part feeding systems: bowl, tube and automated screw feeding

- Sub 1-minute cycle time

- Inline quality test for press data force and distance monitoring

- Run out verification of critical features

- AI-enabled Cognex MAR shaft inspection

- End of line functional tester

- Test data stored locally for track and traceability

- Integrated part washer

- Volumetric dispense station

- High precision casting quality check station

Client Result:

Designed, commissioned, installed, and trained by Ehrhardt Automation. Detailed machine vision and lighting integrated throughout